Kegco Brite Tank, DIY Spunding Valve and Fermenting under pressure.

The Beverage Factory was having a sale on the Kegco Brite Tank, which to me is a perfect vessel for fermenting, dry hopping, and transferring to serving kegs under pressure. I ordered two.

When I received one of the kegs (the other ended up back-ordered), I immediately sent the lid off to Jaybird at NorCal Brewing Solutions to have a thermowell installed. Jaybird’s work is great and the service is quick and flawless.

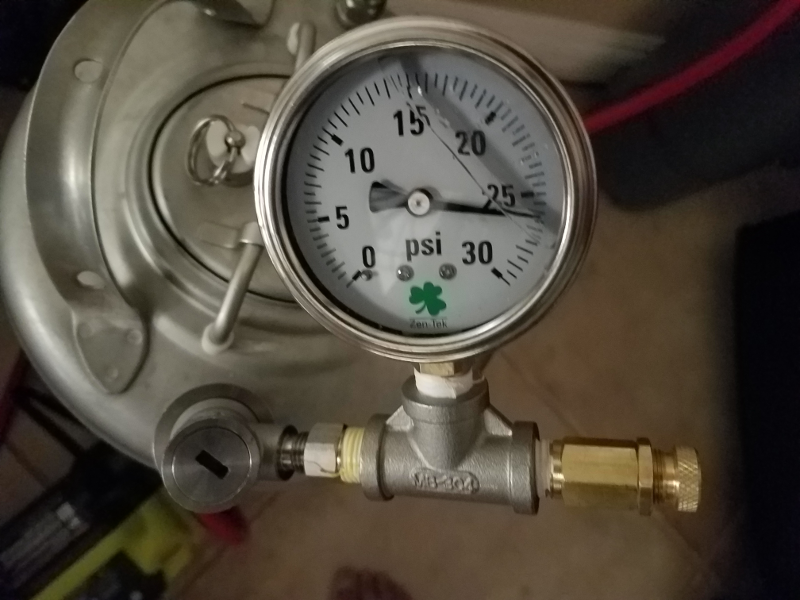

I was also interested in trying to ferment a beer under pressure, so I gathered together the parts and built a spunding valve. Here’s how mine turned out:

I made ten gallons of Dead Ringer IPA, adjusting the hops schedule to accomodate my “no-chill” method, loaded it into the brite tank, let it come down to pitching temperature, pitched the yeast and attached the spunding valve.

Fermentation started right up, and within a day the tank was fermenting under about 8-12 psi. After about 3 days I took a sample out via the liquid out port and checked the SG. Just the right time to start dry hopping!

I depressurized the tank, opened the 4″ tri-clover lid, dumped in the hops, resealed the lid and using my CO2 tank repressurized the tank to 8 psi.

After a few days, I took another SG reading, and it was time to cold crash. Two days later I filled two serving kegs with fresh, carbonated beer that tasted great right out of the tank.